Repairability – More than a label

March 12, 2021

David Connett, Partner at Connett & Unland GbR shares his thoughts on the emerging trend for repairability.

David Connett, Partner at Connett & Unland GbR shares his thoughts on the emerging trend for repairability.

France did it in January and the EU did it in March – They took the first steps to informing consumers about the repairability of the devices they buy at the time they buy them. So why do we want to fix things after nearly forty years of throwing them away?

It is a touchy feely answer that waste is bad for the environment, but it is true. Global warming, erratic weather patterns, dead coral reefs, microplastics in ocean fish and so on and so on. The task of cleaning up plastics and e-waste seems so massive, we are easily tempted to just live our lives. It’s not a case of we don’t care, it’s more a case of we don’t know what to do for the best.

Yet as a humble consumer, you are the power behind the change. Your purchasing decisions can, do and will influence and bring about change. Not on their own, because the task is so massive, legislation is needed to create a common message and action plan.

Do you really need a new phone, or do you need it repaired? Probably a repair because either the screen is broken, the battery needs replacing or the charging socket is damaged, or it needs drying out because you, like me, dropped it in the loo, bath or sink.

At the shop they tell you it can be repaired, but the cost is almost the same as buying a new phone. The question is, is that true, or is it a ruse to get you to buy a new phone, which you don’t really need or want? A new screen costs less than €20 ($24) to manufacture, at €30 ($36) an hour, replacing the screen takes 30 minutes, so you have €15 ($18) of labour. Allow a generous €10 ($12) for overheads and you have a core repair cost of €45 ($54). Let us be generous and add a good profit margin and make a charge of €60 ($72). So why do some phone manufacturers charge a king’s ransom? In my opinion because they can…

According to the TECHWALLS website a new Apple iPhone 11 Pro Max (512GB) costs $490.50 (€420) to manufacture, but Apple sells the phone for $1,449 (€1265), a whopping 66.15% profit. But do not shoot Apple, the other manufacturers do something similar. Well almost all of them, if you want a repairable phone, check out Fairphone.com.

Fixing things means they last longer. You need to make less new ones and you reduce the amount of waste we generate. Fixing things means you create more jobs for fixers that need to be trained, so you create more jobs for technician teachers and so on. You restore a repairability culture that has all but disappeared over the last few generations.

France leading the way with a repairability score for products. Other countries will follow Frances’s example, because they are waking up to the fix it agenda that creates jobs, and reduces linear manufacturing and e-waste. And it starts with a label indicating how easy it is to repair the device.

If you are still with me, you are thinking what has this got to do with office printers? The answer is… A lot. The average printer is used far less than its capacity to print. A3 printers rarely print A3 documents, spending their time printing A4 documents. A bit like having a bus, when you need a car?

The big “thing” about repairability labels is they will start to change consumer mind sets in favour of repair and reuse and that benefits everyone except…

Manufacturers are fighting a rear-guard action to water down and slow down a drive to repairability as a norm. The linear manufacturing model, whoever sustainable it is, is still linear, pulling finite resources out of the ground to make their products that will eventually end up in a hole in the ground. We need manufacturers to start the journey now. Thinking about how the device works, what the fail points might be and then how to repair the device.

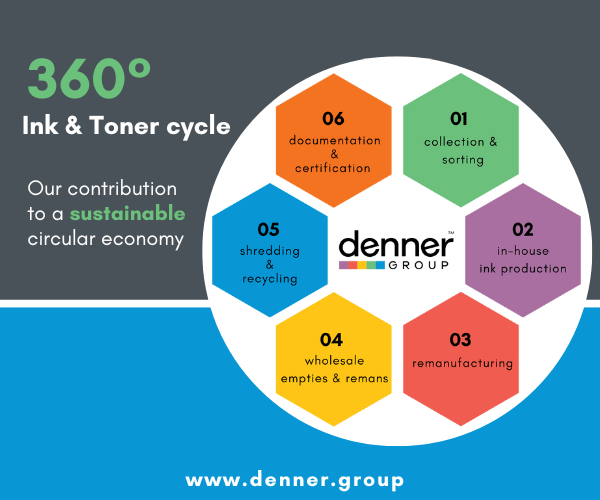

Repair and reuse are a renaissance of human heritage and is at the centre of a circular economy. It is a journey we all have to take whether its voluntary or legislated, but we are all on the journey.

Yes, I am biased – My dad fixed typewriters (yes I am that old). My first project was making a doorbell work. Apart from giving my mum an electric shock (didn’t know about earthing). In my defence I was only nine years old. But I did make my own crystal radio to listen to Radio Caroline the pirate radio station. My early career was as an engineer making things work, oft in extreme and hostile conditions, but there is always a buzz when you pit your skills against technology and make it work.

Categories : World Focus

Tags : EU France Labelling Right to Repair