G&G talks print problems in cold weather conditions

October 26, 2022

Keeping printers productive during cold weather can be quite challenging, so G&G discusses in its latest article how its products are cold resistant.

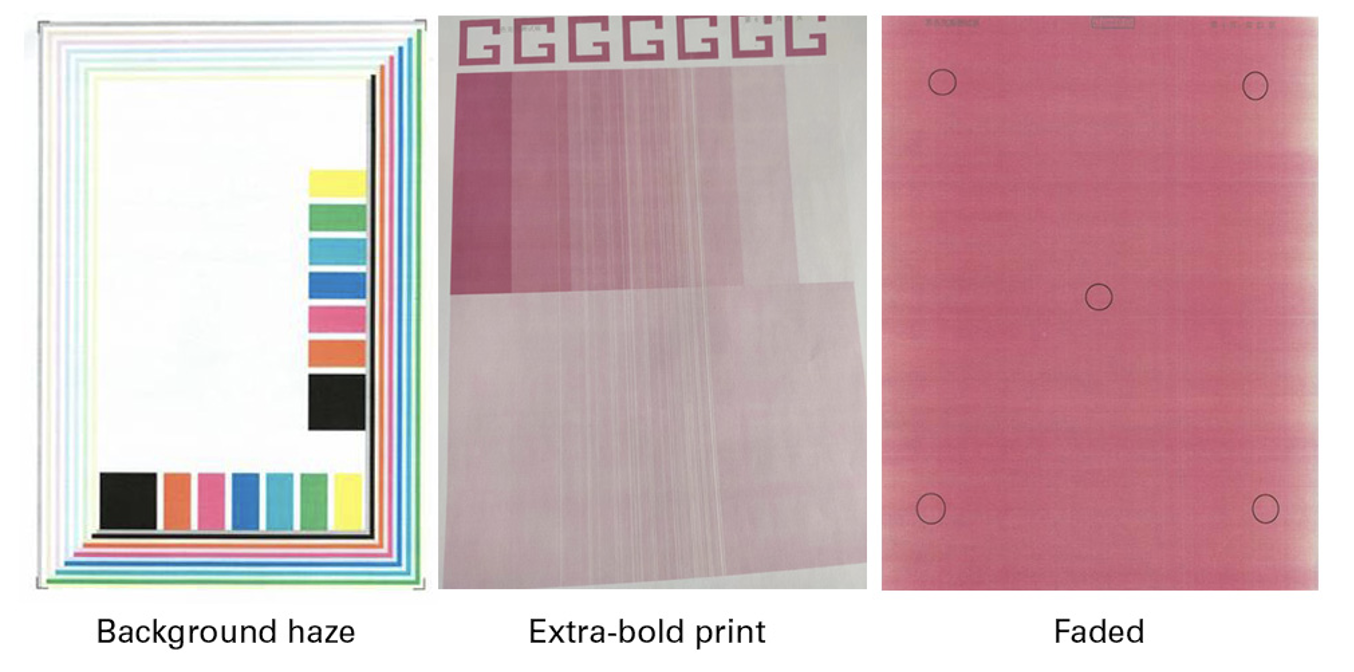

When temperatures drop and the air dries, the presence of excess static can interfere with the print process. Such changes can impact cartridge components and cause problems such as streaks, background haze, fading, light and dark blotches, colour variation or extra-bold print.

All laser printers and toner cartridges are susceptible to static build-up. In addition to interfering with the print process, devices or static-sensitive cartridge components can be damaged when static discharges.

All laser printers and toner cartridges are susceptible to static build-up. In addition to interfering with the print process, devices or static-sensitive cartridge components can be damaged when static discharges.

In addition, certain components inside the cartridges can harden or become deformed which also affects printout quality. G&G explains that for example, the paraffin wax, a key ingredient in toner powders, will increase its hardness as the weather gets colder. The rubber-made coating on the primary charge roller hardens too and this causes an increase in resistance.

The company said:”G&G understands quality begins with raw materials. For toner powder, G&G insists using capillary rheometers to test the soft point of toner powers, ensuring batch-to-batch, and consistent temperature characteristics associated with toner flow during transferring and fixing. This enables G&G to prevent the paraffin wax from hardening in cold weather.”

The company said:”G&G understands quality begins with raw materials. For toner powder, G&G insists using capillary rheometers to test the soft point of toner powers, ensuring batch-to-batch, and consistent temperature characteristics associated with toner flow during transferring and fixing. This enables G&G to prevent the paraffin wax from hardening in cold weather.”

Static-sensitive components, like organic photoconductor (OPC) drums, undergo rigorous tests to ensure outstanding anti-static capability, the company explained.

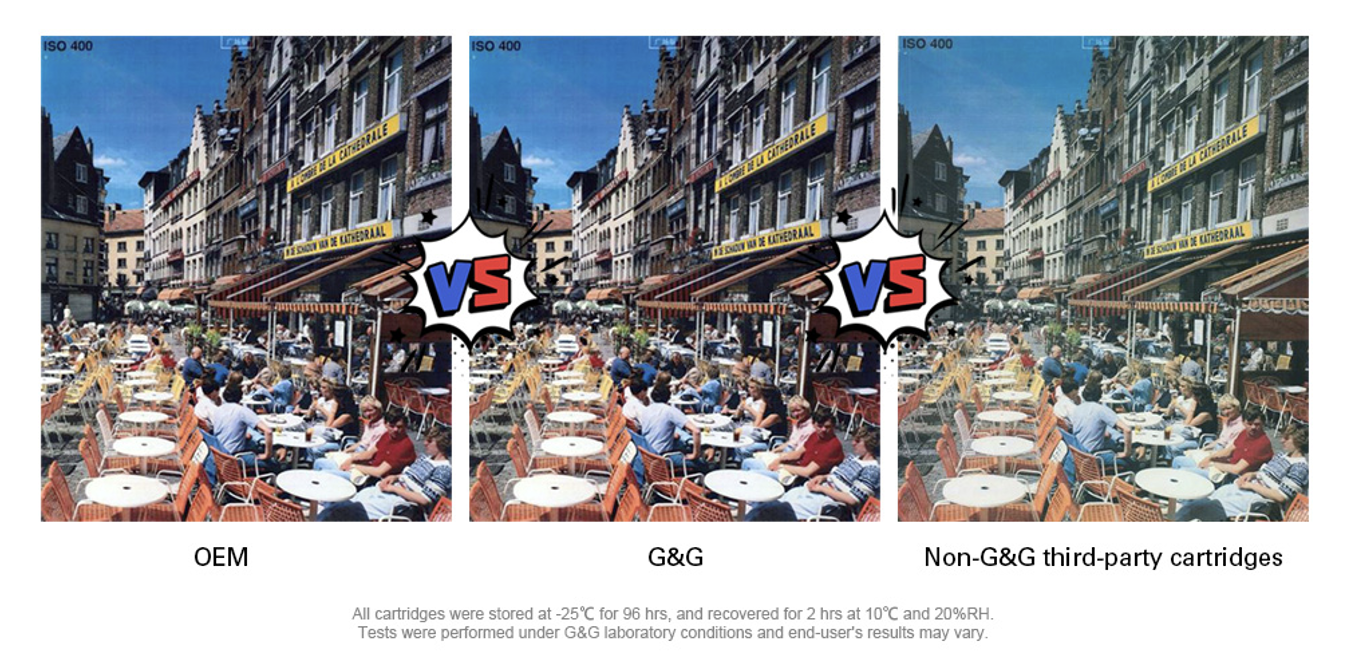

G&G explained that its CMYK cartridges undergo rounds of temperature and humidity tests too. During these tests, samples are subjected to temperature-humidity stress for periods of 12, 16, or 96 hours at temperature levels between -25C and 40C.Humidity levels between 15 and 85%RH are experienced during testing too. G&G added that it achieves consistency in its products through automated production lines.

Categories : Around the Industry

Tags : Automation Cartridges G&G Ninestar Temperature Testing